Foreword

With craft show season rapidly approaching, I wanted to share how to take a closer look at your production costs so you can effectively price your product and see some return on investment.

While there are many other associated costs, for the sake of this blog post we are just going to take a look at the very basics: cost of ingredients, cost of packaging and cost of your time. These simple calculations will help you determine which ingredients to use and will give you a visual and accurate financial plan. Since we’re just turning our hobby into a business, we don’t necessarily need to worry about wholesaling and overhead costs like storefront electricity, employee wages, etc… yet. I am going to use cold process soap for this exercise.

The Breakdown

For demonstrative purposes, let’s say I am going to my first event and I need to know how much profit I can make. The recipe I will be using for this example is one of my more gentle formulations. Even though it’s got a higher Coconut oil percentage, it produces a stable, creamy lather and is great for sensitive skin. (I am excited to walk you through this making recipe in next week’s blog tutorial!)

I normally only make small batches, so to product 10 approximately 4.8-5 oz. bars of soap, the recipe calls for the following:

- 0.9 lb. Coconut Oil (76 Degrees)

- 0.6 lb. Sweet Almond Oil

- 0.5 lb. Rice Bran Oil

- 0.76 lb. Distilled Water

- 0.3 lb. Sodium Hydroxide

I want to scale my recipe up to make a 100-bar batch for the show. Since my original recipe yields 10 bars of soap, I am going to multiply the ingredients by 10 so I can determine how much material I need to purchase.

Just take a look at the savings when buying in larger quantities. Here at Bulk we make it easy to determine your price per pound of product. On each product page, the selection menu will indicate the total price as well as how much you pay per pound. To the left you will see pricing for our Coconut 76 oil. For this endeavor, I’m buying 35 lbs. because I am going to be using a lot in my recipe. One of the advantages of scaling up your business is the ability to buy in bulk, thus saving drastic amounts of money. In today’s economy, it just makes sense.

Review your personal budget and decide if you will save money in the future by purchasing in bulk.

Scaling Up

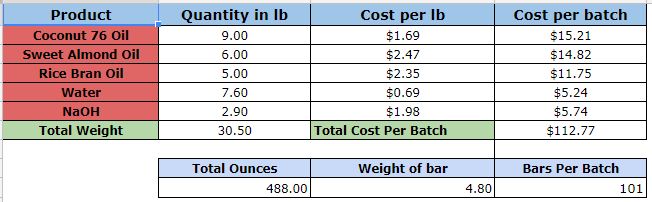

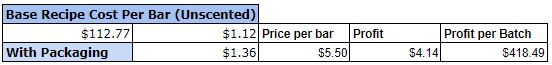

The chart below shows each ingredient broken down in weight and cost per pound and batch. One of my favorite resources for creating spreadsheets and documents is Google Drive due to its ease of sharing and intuitive, user-friendly nature.

Scaling the recipe up to 100 bars will require over 30 lbs. of raw material. This will be over a $100 investment so it is important we calculate our profit margin. Each bar of soap weighs approximately 4.8 oz. which is actually about industry average.

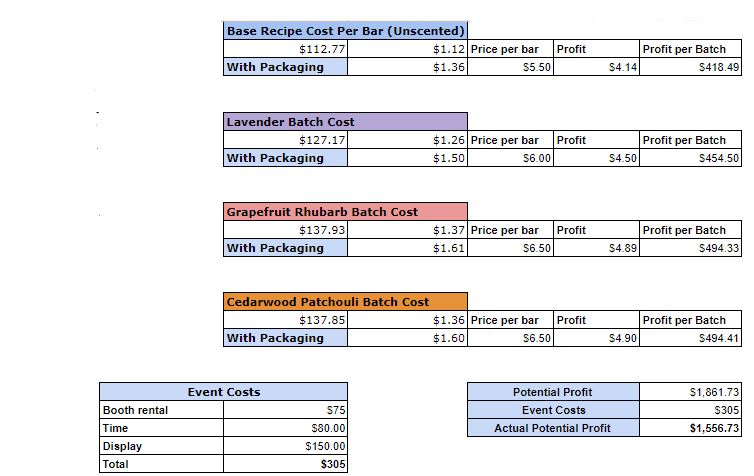

Now it’s time to calculate how much each unscented bar costs. This is the first step to setting your price. A batch of unscented soap will cost me $52.77 in materials, but I need to make sure I pay myself for this, too! This is built into the cost of each bar by deciding how much I want to pay myself per hour, multiplied by how many hours I put into a batch from beginning to end. I’ve found that on average, a batch takes me roughly a collective three hours. I’ve decided I am worth $20/hr for this venture. This will add $60.00 worth of labor into the cost of my soap. When I divide that by my yield of 100 bars, my cost works out to be $1.12 per bar. Since I bought my ingredients in larger quantities, I was able to save more more money, therefore increasing my profit margin.

On Fragrances & Variety

I want to have a variety to offer my customers so I need to factor in the cost of the fragrances I’d like to offer. This works pretty much like my base oils, and I like to figure this pricing by utilizing the price per pound displayed on the Bulk Apothecary website. I multiply the weight of the fragrance oil in pounds by cost per pound so I am able to determine that I need 1.22 lbs. of Lavender fragrance oil, which costs $11.81/lb. In this example, you can see I also did some pricing for Grapefruit Rhubarb and Cedarwood Patchouli fragrance as well. Having the price per pound displayed on the website helps me calculate whether or not a particular fragrance oil would be cost effective.

It might seem like I am at my final cost per bar but we’ve got one more factor to consider – packaging. Presentation is important, but I don’t want to lose any potential profit by using expensive packaging just because it’s pretty, especially for my first event. So, I decided on simple shrink wrap sleeves for $0.11 each and well-designed professional looking labels for $0.13 each.

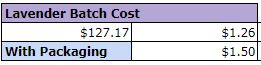

So, back to the Lavender example – I set my spreadsheet up to add my total packaging cost of $0.24 ($0.11 + $0.13 = $0.24) to my individual bar cost giving me a final Lavender bar cost of $1.36.

A common price I’ve seen at local craft shows is between $5 and $8, but that may vary depending on your location. It is important to also take into consideration the varying markets and sales trends of your area.

I decided to set the Lavender bar at $6 for the purposes of this exercise. If I charge $6 and it costs $1.50 to make the bar, packaging included, I could potentially make a profit of over $450.

Once I have done this for all of my fragrances, I can begin to anticipate my potential profit at the craft event. I did this by adding my potential profit for all 4 varieties and then subtracting the costs to participate in the event – booth fee, time at the event, display materials etc. I calculated this to be about $305. Now that I am able to factor in these costs, let’s take a look at my potential event profit:

I can now see that my potential event profit is over $1,500.00 – wow!

In Conclusion

Let’s face it – this definitely isn’t the fun part of starting your own business, but what is fun is seeing what potential your financial future holds. Once you have a spreadsheet established, you can begin to adapt this model to any products you may be selling, or even to keep track of your own personal budget. Often as Artisans we get caught up in all the making that we forget that numbers, too, are very important.

Do you see why buying in bulk can help save you money? What has helped you scale up your production or track your sales? Please let us know in the comment section below. We would love to hear from you!

Great information on calculating costs. I can’t wait to read through our recipe steps in the next blog post.

Thank you! Nina

Glad you like it Nina!

This post and all of the others have been so helpful as I start my new business. Thank you so much!

Glad it helps!

New to everything Goat Soap…… I need to break this down and recalculate for the Melt & Pour base fragrance. I love how informative this page is THANK YOU!!

Glad it helps; you’re welcome!